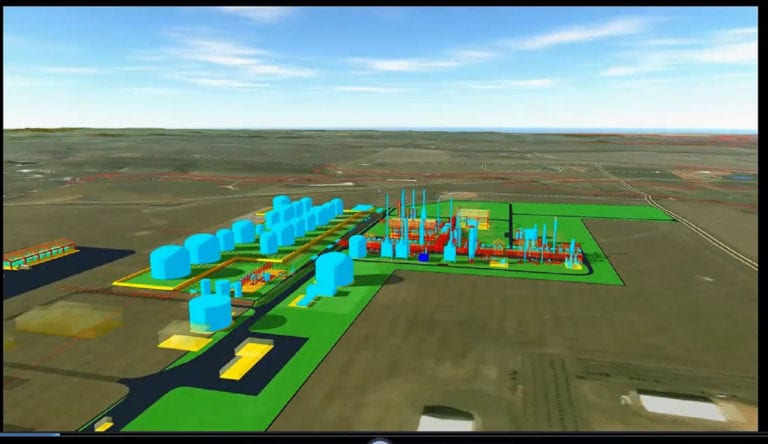

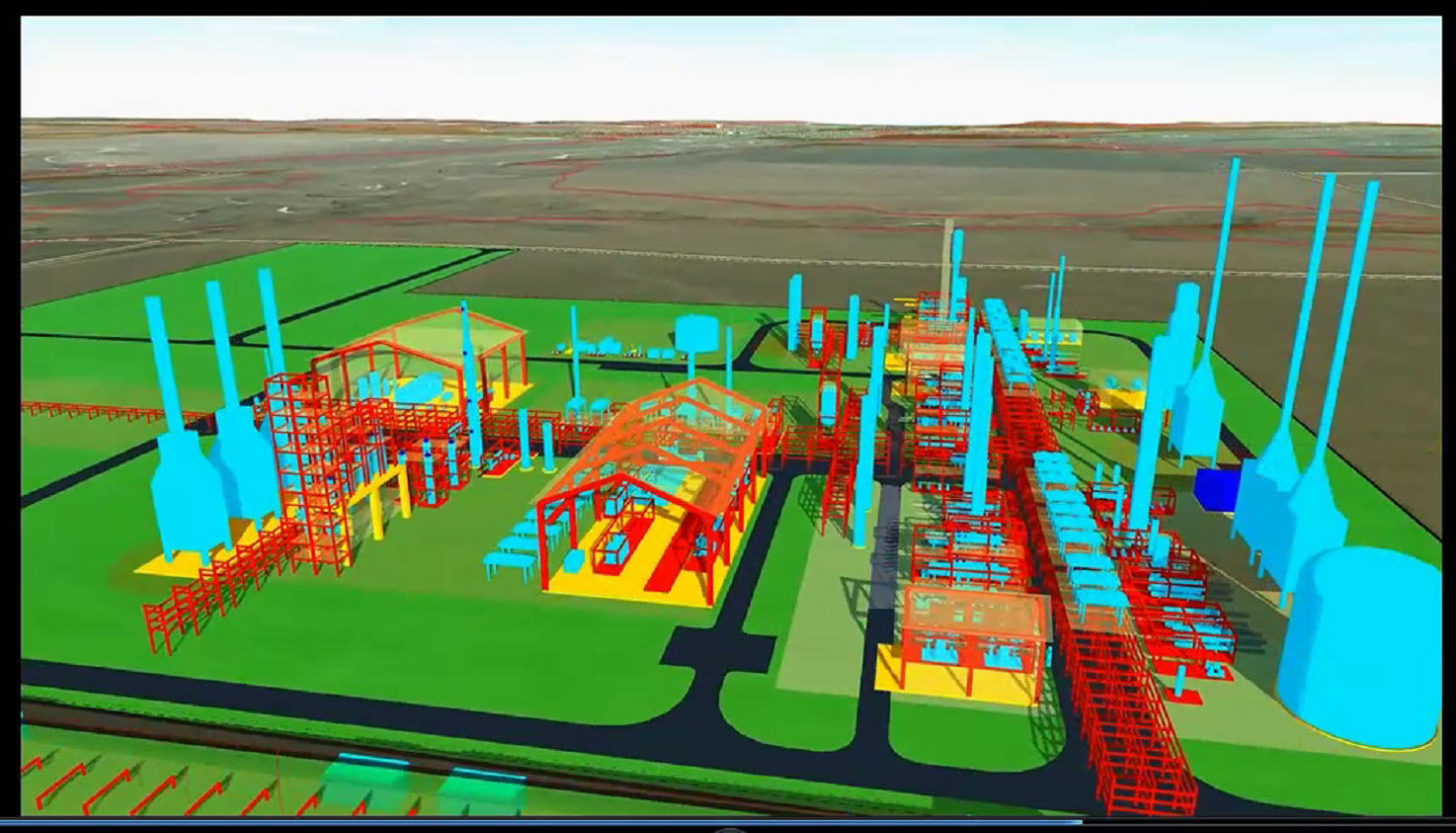

Meridian Davis, the refinery that boasts it will be the greenest refinery on the planet when completed, has put another green feather in its cap.

The company has signed an agreement with the city of Dickinson to take its treated wastewater to use in the refinery, and then return that water to the city for treatment and reuse.

“Dickinson generates waste water that they clean to standards that allow them to discharge it to the environment,” said Dan Hedrington, a spokesperson for Meridian Davis. “It’s an effort that the city has to undertake that doesn’t generate revenue for them if they discharge it to the surface water system, the rivers. And the process also takes energy, which is being wasted by being discharged into rivers.”

“Dickinson generates waste water that they clean to standards that allow them to discharge it to the environment,” said Dan Hedrington, a spokesperson for Meridian Davis. “It’s an effort that the city has to undertake that doesn’t generate revenue for them if they discharge it to the surface water system, the rivers. And the process also takes energy, which is being wasted by being discharged into rivers.”

The agreement with Meridian will allow the Dickinson to make something off treating its wastewater, not just once, but twice. Under the agreement, Meridian will pay the use of the treated water, as well as for taking the water away to treat it again.

The agreement will also mean that the Davis Refinery won’t need to drill a well or allocate water from the Dakota Aquifer. Nor will it need septic treatment for its industrial water use.

“It will all be going back to Dickinson,” Hederington said. “So it’s less use of a natural resource that is already available and being discharged into the rivers by the city of Dickinson.”

This is just one in a series of moves the company has taken to ensure its greenfield refinery will live up to the claim of greenest in the world.

The refinery will also have all the latest greatest technology for clean emissions.

The fuel gas coming in will be scrubbed for sulfur so that sulfur oxides, or SOx, won’t be produced to any appreciable degree.

Ultra low burners will be used, to prevent the formation of nitrous oxides, or NOx. And a catalyst will be used in the stack itself, to reduce carbon dioxide and monoxide emissions, or COx.

The plant will also include optical gas imaging to monitor the system around the clock for fugitive hydrocarbon emissions, or volatile Organic compounds. These are referred to as VOCs.

Typically, refineries use a handheld sensor for this, and just inspect on a regular schedule. But that can leave quite a few days where greenhouse gases are being released to the atmosphere.

An optical sensor, on the other hand, can run constantly and immediately sense if there are fugitive emissions.

“That means you can spot a leak on the first day,” said Mark Fonda, chief engineer for Meridian Energy Group. “We will be the first refinery to use that over the entire plant.

As a result of these technologies, emissions from the Davis Refinery will be so low that the facility has qualified as a synthetic minor source. That, in and of itself, already makes the plant unique.

“There’s never been a full conversion refinery that has qualified as a minor source, and we will be the first,” Fonda said. “That means each of those four components will be less than 100 tons per year.”

The plant will also use vapor recovery to minimize any flaring. Vapors collected by that system will be cycled back into the refinery as fuel. Flaring will be limited to 168 hours or less annually.

Many refineries a noticeable white plume of water vapor rising up from a cooling tower. Davis will not be using a traditional cooling tower, however. It will be using an air cooler instead, similar to the radiator on a car.

That will help minimize the plant’s visual footprint, Fonda said.

“We are looking at sight, sound and smell, trying to produce a minimal footprint on all three levels.”

Leave A Comment